フローティングフロアマットへの XPE フォームおよび IXPE フォーム素材の適用

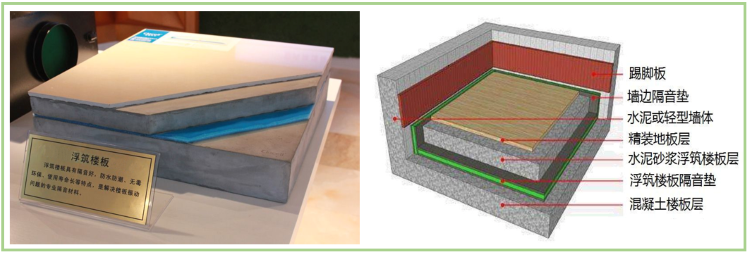

Floating floor is a new application of XPE IXPE foam material developed by Chinese enterprises in recent years in response to the government's call for energy conservation, emission reduction and carbon neutrality standards. It is to place XPE IXPE foam material between the layers of the house, which has the effects of shock absorption and heat preservation, sound insulation and noise reduction, health and energy saving, so as to achieve the standard of green building.

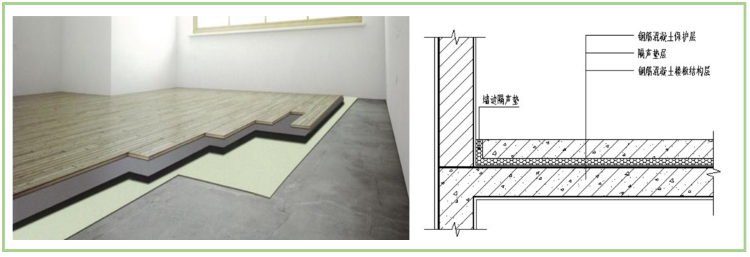

The construction principle of the floating floor is as follows:

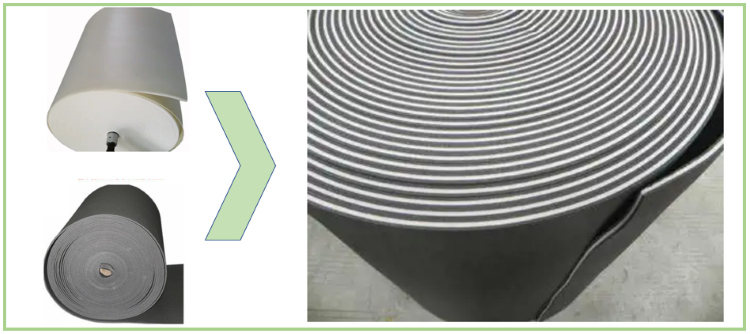

The sound insulation material in the floating floor slab is XPE IXPE foam material, and its production process is as follows: 1. According to a certain ratio of raw materials such as PE, masterbatch particles are produced by the kneading and granulating unit of the XPE IXPE Foam machine line. 2. After mixing the PE and the master batch produced in the first step according to another formula, the master sheet is produced by the master sheet extruding unit of the XPE IXPE Foam machine line. If DCP is added in this step, XPE foam material is produced, and the third step can be directly skipped into the foaming machine for foaming process. 3. The master sheet produced in the second step is subjected to the cross-linking process through the irradiation unit of the XPE IXPE Foam machine line. 4. The DCP-added master sheet or the irradiated master sheet is foamed through the foaming machine unit of the XPE IXPE Foam machine line to obtain XPE Foam or IXPE Foam material. 5. Pass the thin XPE IXPE foam material through the secondary processing unit of the XPE IXPE Foam machine line for the thickening process. Usually, a layer of 4~5mm black XPE IXPE foam material is sandwiched between 2 layers of 3mm black XPE IXPE foam material, so as to obtain a composite material with a thickness of 10~11mm. Through the above 5 steps, the sound insulation material for floating floor is completed.

https://youtube.com/shorts/EyJufS_SD7w

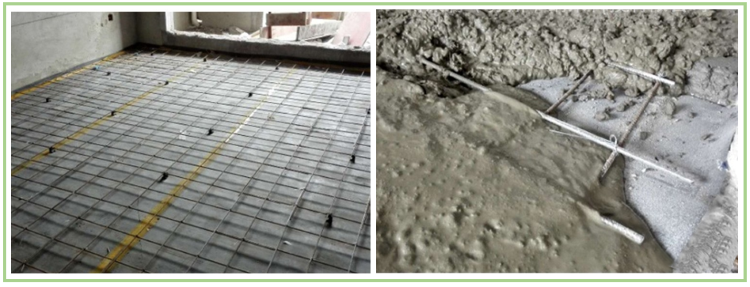

The construction method of the floating floor is: ① build a 80mm reinforced concrete floor; ② on the 80mm reinforced concrete floor, lay 10~11mm XPE IXPE foam material; ③ lay a steel frame on the top of ②, and pour 40mm cement layer. In this way, the entire production process of the floating floor slab is completed.

The floating floor obtained by the above method has been tested:

With a thickness of 6mm, the weighted normalized impact sound pressure level can be improved by more than 19 dB

With a thickness of 8mm, the weighted and normalized impact sound pressure level can be improved by more than 20 dB

With a thickness of 11mm, the weighted and normalized impact sound pressure level can be improved by more than 22 dB.